Home / FAQs

FLOCELL

Frequently Asked Questions

XFM stands for Extra Fines Mechanical. Flocell XFM Fines Filter is an open cell mechanical filter that utilises open cell filtration technology to filter water to a high quality, whilst also having the potential to save water and energy.

Flocell media is made from Virgin grade HDPE.

Flocell products; filter and media, are manufactured in Wigan, England.

The open cell media used in our Flocell filters work by settlement not entrapment (like sand or glass). Each cell is in essence a mini lamella seperator.

Any debris entering the filter bed will lose kinetic energy as it passes through the filter pack until it settles out in or on one of the elements.

As there is 80% free area in a piece of Flocell media compared with sand’s 5%, the Flocell media can hold significantly more debris before backwashing is required.

Its large free area results in less resistance to water, which means a greater flow with negligible head loss can be obtained.

Flocell media can hold more debris than traditional media before a backwash is required, so the frequency of backwashing can be reduced. The amount of water required to clean Flocell media is only the volume of the filter itself.

The open area of Flocell media results in less resistance to water than with traditional media which allows for either a smaller pump to be utilised (using less electricity) or a variable speed pump can be configured at a lower speed to reduce electrical consumption. As an example, we expect to see approximately 20% greater flow through our media than through sand. Using the pump affinity laws, this means the speed of the pump can be reduced by 20% to achieve the same flow and this equates to a reduction in electricity consumption of 48.8%.

Energy is also saved due to reduced cleaning frequency. This is especially important when heated water is being remediated and then lost to waste.

Flocell XFM Fines Filters provide a constant flow rate, at a constant pressure, so turnover times and the circulation of water is always maintained.

Any equipment which requires a constant flow will never stop working on “no flow”. The filtration quality is also maintained, unlike sand or glass which varies according to how blocked the media is.

Flocell media is also 87.5% lighter than sand making it easy to handle and reduced transport costs and associated carbon balance. The open nature of Flocell media ensures the filter bed will be oxygenated (if necessary) by influent water there are never any unwanted anaerobic conditions or channelling issues within the filter pack.

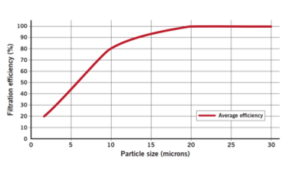

Flocell media has been independently tested by IFTS (Institut de la Filtration et des Techniques Separatives) in France to EN16713-1.

Flocell XFM Fines Filters can be used in a wide range of filtration rates depending on the conditions that are encountered.

It is more important to ensure there is good circulation in the water (no dead areas with no circulation) and that the turnover times of the water per day are within acceptable standards.

Yes, Flocell media are not subject to degradation by ozone.

Flocell XFM Fines Filters can filter particles as small as 1 micron. An independent test report can be found on our website FlocellFiltration.com

Flocell filters will require less backwashing than traditional media, however each installation is different. We typically find that the increased retention capacity means that a filter cleaned daily can be left for a number of weeks before needing cleaning.

We do not publish absolute performance information as every system installed is operated differently. IFTS have independently validated the particle size efficiency but absolute performance is a function of loading rates, particle size distribution and flow rates.

Flocell can undertake Particle Size Analysis for customers at very competitive rates if required.

Our Flocell Bio Media are available in bulk bags of nominal 2.5m3. Small quantities can often be delivered immediately from stock but we would ask you to contact our team for larger deliveries which can be made direct to site where required. As well as providing a range of our bio media elements we can also work on bespoke media design where needed and have and can help source rapid prototyping tools when required.